What Type of Cost Are Batteries for the Renewable-Energy Industry?

Key Components Influencing Renewable Battery Costs

The costs of batteries for the renewable energy industry are impacted by various factors, including raw material prices, manufacturing processes, and supply chain challenges. For Lithium Iron Phosphate (LFP) batteries, the prices of lithium, iron, and phosphate can fluctuate based on global demand, especially from the electric vehicle and renewable energy sectors. While lithium tends to experience volatility, iron and phosphate show more stability. GSL ENERGY leverages the cost advantages of these abundant materials, ensuring high-performance, affordable LFP battery solutions for large-scale energy storage.

Manufacturing Efficiency and Cost Reduction

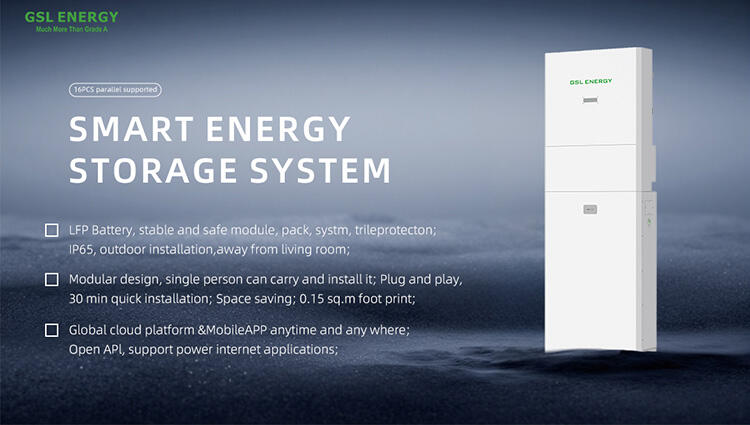

The production of LFP batteries involves complex processes such as electrode coating, electrolyte filling, and thermal sealing. GSL ENERGY addresses these challenges by utilizing automated production lines and modular assembly techniques, minimizing labor costs and material wastage. This streamlining allows for consistency in production and scalability, which helps industrial users achieve long-term savings. Their flagship High Voltage LFP Battery Cabinets are a prime example of this approach.

Supply Chain Resilience in Battery Production

Global supply chain issues, including geopolitical risks, material shortages, and logistical barriers, continue to affect battery availability and costs. To address this, GSL ENERGY has established a robust logistics network, ensuring timely delivery across Europe, Southeast Asia, and North America. This resilience makes GSL ENERGY a reliable partner for commercial solar battery projects, where timely system deployment is critical.

Benefits of LFP Batteries Over Traditional Lithium-Ion

LFP batteries offer a lower cost per kWh compared to traditional lithium-ion batteries (NMC/NCA), along with superior safety and longer life cycles. These features make LFP batteries especially attractive for commercial energy storage systems, where minimizing downtime and maximizing ROI are crucial. GSL ENERGY’s 48V Rack-Mounted Battery Systems are widely adopted in industrial settings, including factories and microgrids, due to their cost-effectiveness and enhanced thermal management, which reduce maintenance needs.

Longevity and Safety of LFP Battery Systems

GSL ENERGY’s LFP battery systems are designed for longevity, offering over 6,000 cycles at 80% depth of discharge, which can last more than a decade. This durability reduces replacement costs and maximizes investment returns, especially for critical operations such as telecom towers, data centers, and solar farms. Additionally, LFP batteries are known for their thermal stability and low fire risk, leading to lower insurance premiums and compliance costs.

Policy Incentives and Tax Credits

Government incentives, such as the U.S. Inflation Reduction Act (IRA), which offers a 30% tax credit on battery energy storage systems, have boosted the demand for commercial storage solutions. GSL ENERGY offers systems that comply with U.S. regulatory standards, ensuring clients benefit from these tax credits. State-level rebates further reduce installation costs for businesses in areas like California, New York, and Hawaii, helping clients lower their upfront expenses by up to 40%.

Emerging Technologies and Future Cost Trends

The future of battery storage will be shaped by AI-driven optimization and green innovation. GSL ENERGY consistently uses brand-new A-grade lithium iron phosphate battery cells to ensure high performance and long life for its systems, avoiding the safety and performance risks that may come with recycled batteries. At the same time, the company supports eco-friendly design and efficient supply chains to lower life cycle costs and help with sustainable energy development.